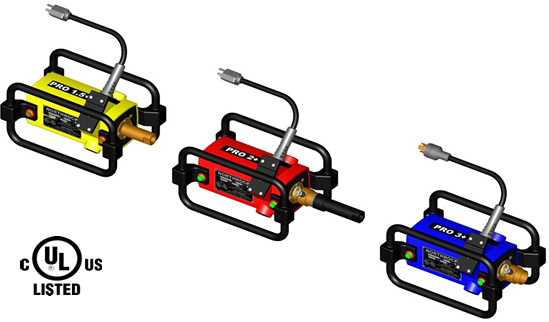

Northrock Pro Series Electric Vibrators

Heavy-Duty. Hard Hitting. Made in the USA.

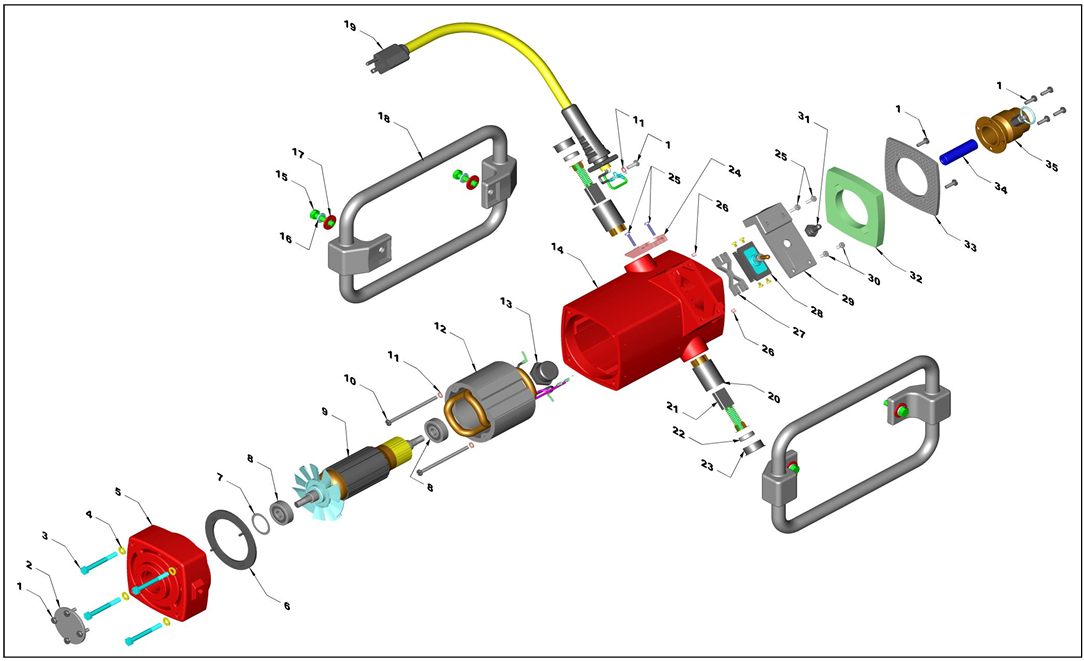

- Built to take a beating: High-strength cast aluminum housing dissipates potentially damaging heat

- Rugged Protection: Shock-absorbing frame protects the motor and doubles as a convenient carrying handle.

- Job Site Ready: Equipped with watertight, strain-relief power cords to handle abuse.

- Easy Maintenance: Features easy access to oversized brushes for quick service

- Universal Fit: Interchangeable with all other major brands.

Model Specifications

| Model | HP | Amps | Weight | Max Head Size | Application |

|---|---|---|---|---|---|

| PRO 1.5+ | 1.5 HP | 13 Amp | 17 lbs | 1-3/4" | Small jobs, tight rebar, walls. |

| PRO 2+ | 2 HP | 15 Amp | 19 lbs | 2-1/2" | The industry workhorse. Most versatile option. |

| PRO 3+ | 3 HP | 19 Amp | 25 lbs | 2-1/2" | Continuous duty, low-slump concrete. |

Choose Your Motor Size

Northrock System Builder

Select your requirements to find the perfect Northrock Motor.

How to Select Your NorthRock System

Step 1: Determine Head Diameter

First, determine the diameter of the head based on the radius of influence needed, as listed in the chart below.

| Head Dia. | Radius of Influence |

|---|---|

| 3/4" (19mm) | 4 inches (102mm) |

| 1" (25mm) | 5 inches (127mm) |

| 1-1/4" (32mm) | 7 inches (178mm) |

| 1-1/2" (38mm) | 14 inches (356mm) |

| 1-3/4" (44mm) | 18 inches (457mm) |

Step 2: Determine Shaft Length

Determine the length of the shaft needed to reach the bottom of the form.

- Note: Standard lengths are 2' to 21'

- Shafts can be connected to reach up to 60'

Vibrator Head Performance

Match the head size to your specific job requirements.

| Head Dia. | Radius of Influence | Centrifugal Force | Capacity (Y3/hr) |

|---|---|---|---|

| 3/4" | 4" | 112 lbs | 4 |

| 1" | 5" | 183 lbs | 6 |

| 1-1/4" | 7" | 430 lbs | 8 |

| 1-1/2" | 14" | 760 lbs | 12 |

| 1-3/4" | 18" | 1,100 lbs | 24 |

| 2" | 22" | 1,450 lbs | 35 |

| 2-1/2" | 28" | 1,525 lbs | 37 |

Why Northrock Electric Vibrators

The industry standard for internal concrete consolidation.

Interchangeable Design

Don't get locked into proprietary parts. Our motors are fully compatible with shafts and heads from all other major brands, making fleet management simple.

Cool Running

Built to last. We use high-strength cast aluminum housings which dissipate heat significantly better than the plastic housings used by competitors.

Job Site Ready

Tougher than the environment. Our units feature a water-tight strain relief system that prevents accidental cord pull-outs during heavy use.

Easy Maintenance

Service in the field, not the shop. We use oversized brushes with easy-access caps, allowing for quick inspection and replacement without disassembling the motor.

System Flexibility

One motor, endless options. Our power units can drive flexible shafts ranging from 2’ to 21’ and vibrator heads from 3/4” to 2-1/2”.

Made in the USA

Quality you can trust. Every Northrock electric vibrator is designed and manufactured in our Bohemia, New York facility.

Parts & Compatibility

Flexible Shaft Options

- Standard Duty Shafts: Stiffer construction for better poking control.

- Pencil Shafts: More flexible, designed for tight areas (used only with 3/4" and 1-1/4" heads)

- Lengths: Available in 1’ to 30’ lengths. Lengths up to 60’ are available via a simple shaft connector.

Universal Compatibility

Northrock motors and shafts are designed to work with what you already own. We offer adapters for the following brands:

- Oztec Style (1.2, 1.8, 2.4, 3.2 HP)

- Wacker Style (M1000, M2000, M3000)

- Wyco Style (990, 992, 993 series)

- Other styles: Stow, Stone, and Multiquip (Mikasa)

Which Pro Series motor is right for my job?

The correct motor depends on the diameter of the vibrator head you need for the pour.

-

Pro 1.5: Ideal for smaller jobs. It powers heads up to 1-1/2 inches in diameter.

-

Pro 2+: Our most versatile motor. It drives heads up to 2-1/2 inches

-

Pro 3+: The heavy-duty workhorse. Designed for the most demanding applications, including low-slump concrete and continuous use at precast plants

Are Northrock shafts and heads compatible with other equipment?

Yes. Northrock systems use a universal countershaft that can accommodate most brands of vibrator heads and shafts—with the appropriate adapter—so your existing inventory can typically be used with a Northrock motor.

How durable are the motor housings?

We build them for the harsh reality of a job site. Northrock electric motors are protected by a high-strength cast aluminum housing that acts as a heat sink to dissipate potentially damaging heat. Additionally, a rugged shock-absorbing frame wraps around the housing to protect the motor and switches from drops and impact.

Do the vibrator heads require maintenance?

No. Northrock vibrator heads are factory sealed and require no maintenance. The internal high-performance eccentrics and precision ball bearings are permanently sealed in a synthetic oil bath

What is the maximum shaft length available?

We stock standard flexible shafts ranging from 2 feet to 25 feet. However, single lengths of up to 30 feet are available, and shafts can be connected using a simple shaft connector to reach lengths of up to 60 feet for deep pours.

When should I upgrade to the Pro 3+ (3 HP) motor?

We recommend upgrading to the 3 HP Pro 3+ unit if:

- You are pouring low-slump concrete or facing abnormal conditions that restrict flow.

- The unit will run continuously, such as in a precast plant environment

- You are using shaft connectors to extend the total shaft length.

- You need to ensure the frequency never drops below 10,000 VPM under any circumstance

Do you offer protection for epoxy-coated rebar?

Yes. We offer coated heads (ranging from 1-1/2" to 2-1/2" diameter) specifically designed to protect epoxy-coated rebar from nicks that accelerate corrosion. We also offer soft-tipped heads to prevent marring when vibrating against expensive forms

Explore Our Inventory

Browse our full inventory of American-made concrete consolidation and finishing equipment.